Sharpening

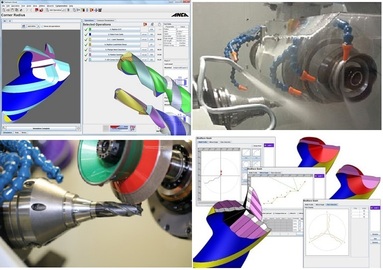

Your tools will be sharpened on modern, heavy-duty machines, the same type used in the manufacturing process. CNC equipment and the use of super-fine abrasives ensure ultimate sharpening accuracy and longer lasting cutting edges. Each item is properly cleaned and individually inspected before the sharpening process to easily allow original specifications to be replicated.

The following items are regularly serviced in our shop:

Carbide Saw Blades

Dado Sets

Shaper Cutters

Planer and Jointer Knives

Router Bits

Spiral and Boring Bits

Insert Tooling

Moulder Knives

The following items are regularly serviced in our shop:

Carbide Saw Blades

Dado Sets

Shaper Cutters

Planer and Jointer Knives

Router Bits

Spiral and Boring Bits

Insert Tooling

Moulder Knives

Custom Tooling

With our fully automated profile grinder we are capable of manufacturing and resharpening your specific tooling. From a wood sample or scanned drawing we can exactly create the knives you need for your project. The majority of thes items are done in-house for rapid turnaround.

Some examples of the types of custom tooling we offer:

Moulder knives

Shaper knives

Profile inserts

Carbide cutters and router bits

Diamond tooling

Templates

Checking gauges

Some examples of the types of custom tooling we offer:

Moulder knives

Shaper knives

Profile inserts

Carbide cutters and router bits

Diamond tooling

Templates

Checking gauges

Ophoven Saw Service | 12000 Riverwood Drive | Burnsville, MN | Tel: 952-894-0262 | Fax: 952-890-0058